The Nuts and Bolts of Container Shipping

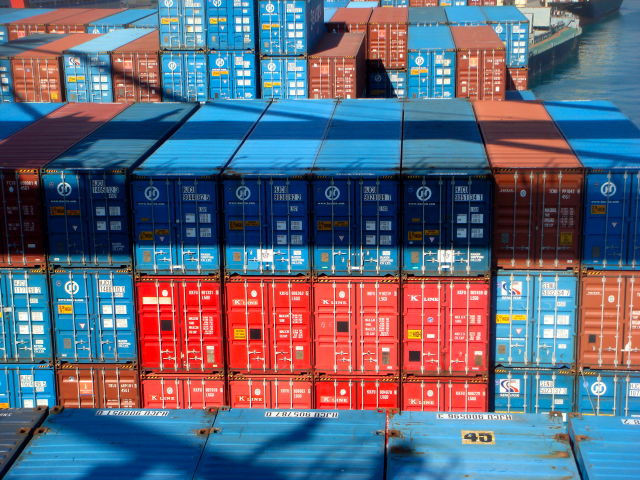

You probably have never really thought too much about container shipping, beyond the obvious: It's a

smart way to get a lot of stuff from here to there or there to here. And, it isn't particularly subtle: Big ships

carry big boxes that can be mechanically loaded and unloaded. But, when it's all put together and

operating smoothly, it's pretty interesting. So, let us give you the low down!

|

|

|

| |

|

|

|

| Chaos |

When a container ship is unloading/loading, it at first seems like total chaos. In actuality, it's a ballet

of big steel stuff. This is our first view (out the van window) when we arrived at the dock in Tokyo.

What we didn't know, but is clearly visible here is: Three cranes are

operating, the usual number for us; you can see two ahead, each with a

container in the air (brown near, blue far), and we're under one.

Trucks are queued to receive or deliver containers to the cranes. The

big orange apparatus to the left is the outside wheels for the crane

we're under. The salt water is two meters away on its other side.

|

|

|

| Alignment |

The

containers go on in ranks; this filling rank of small containers is

just behind the "building", the tall superstructure where the bridge,

living quarters, equipment, and engine room are located. The crane

operator aligns with a rank and empties/fills it before moving on.

Notice the narrow gray walkways between the ranks -- we return to them,

later. (This picture is from Kaoshiung Taiwan, which didn't use trucks,

but "crane-lets" that just dropped the containers on the pavement.)

|

|

|

| The Plan |

This is a portion of our discharge plan from Hong Kong. There are two things to notice.

First, from upper right the plan shows the ranks from the front of the ship to the back -- see the

cross-sectional profile getting larger. Second, notice the horizontal gray bars. Those are hatch

covers that form the deck of the ship. Containers are stored below deck, stacked 9 high in the

middle, and stacked on the hatch covers above deck 6-7 high.

The identity

of every container in every position is recorded.

|

|

|

| Hatch Covers |

Obviously, to put containers in the hold, the hatch covers have to be removed ... and

before they come off, all the stuff above them has to come off. It takes an amazing amount

of planning. The crane operators, the ground crew and the pick-up/delivery team out in the

yard need to be perfectly coordinated. When the hatch is being filled, a man on the ground

checks off each container.

|

|

|

|

x x

|

|

|

| Cover Up |

Hatch covers are huge and heavy. These two, which have been sitting here while the

hatch was loaded, are being returned to position. The two guys in baby blue hardhats are

assisting the crane operator in aligning the gondola to lock on to the cover.

(Notice the "wheels" of the crane.)

|

|

|

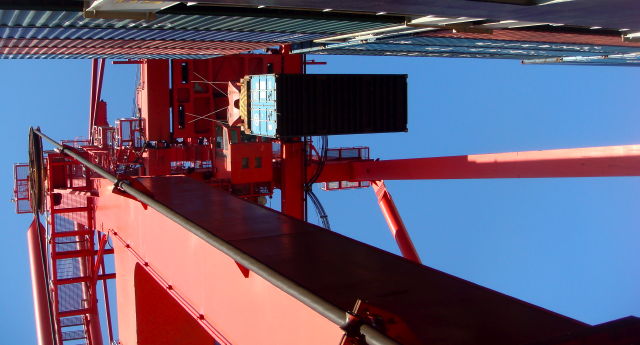

| Heads Up |

Their usual view of the operation is dramatic!

|

|

|

| 3D Tetris |

The crane driver sits in the cab and shuttles forward and backward above the

gondola, aligning it over a container, locking on, picking it up, moving it, and

setting it down. He spends hours looking between his feet focused ten stories below; he needs extremely

accurate depth perception. The best (Tokyo and Osaka) can do a cycle in 80 seconds.

|

|

|

| Onesies & Twosies |

There are basically two sizes of containers, regular and double. Operators sometimes get

them in pairs, but more typically they load them one at a time. To put two smalls end to end

separately requires realigning the crane, so it is reasonably rare.

Notice that the operator can shorten or expand the gondola to match the

size of the container. Also, notice the wings sticking up at the

corners, these can be flipped down to help align in a pick up, but have

to be up out of the way for a delivery.

|

|

|

| Landing |

The ground crew puts a lock on each corner of each container to be loaded. When the container's weight rests on the locks, they

lock. The bright yellow nubs on them are pulled in to show they are locked.

|

|

|

| Lock Down |

Once loaded, the lower deck containers are tied in so that the stack doesn't sway in high

seas. The guys who do this use the gray walk ways between the ranks. It's not a glam job.

|

|

|

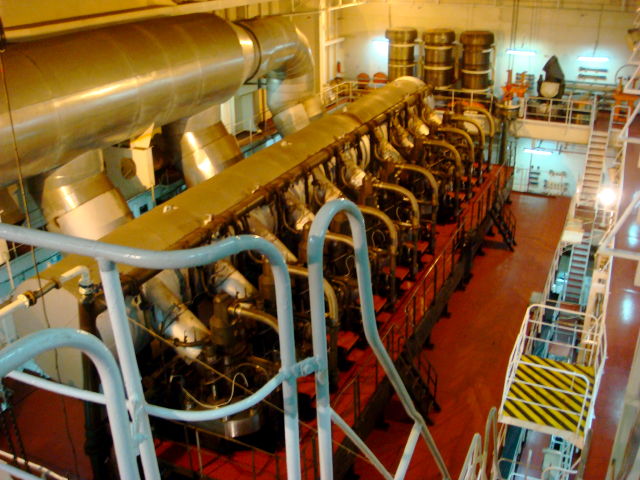

| Engine Room |

The heart of the ship is the engine -- on our tour, we held on to the fuel line of one of the

ten cylinders and felt its beat (86 rpm). The stats are amazing, including its 240 tonnes per

day fuel consumption.

|

|

|

| Control Room |

The engine room team thought of their control room as the "brain" of the ship.

|

|

|

| Bridge |

But we suspect the captain and most of the officers think of the bridge as the brain.

|

|

|

| Life of the Ship |

Whatever. We are sure we know what the "cells" of this huge organism are!

|

|

|